LCD display supplier

——Your Trusted LCD Display Manufacturer for High-Resolution, Energy-Efficient Solutions

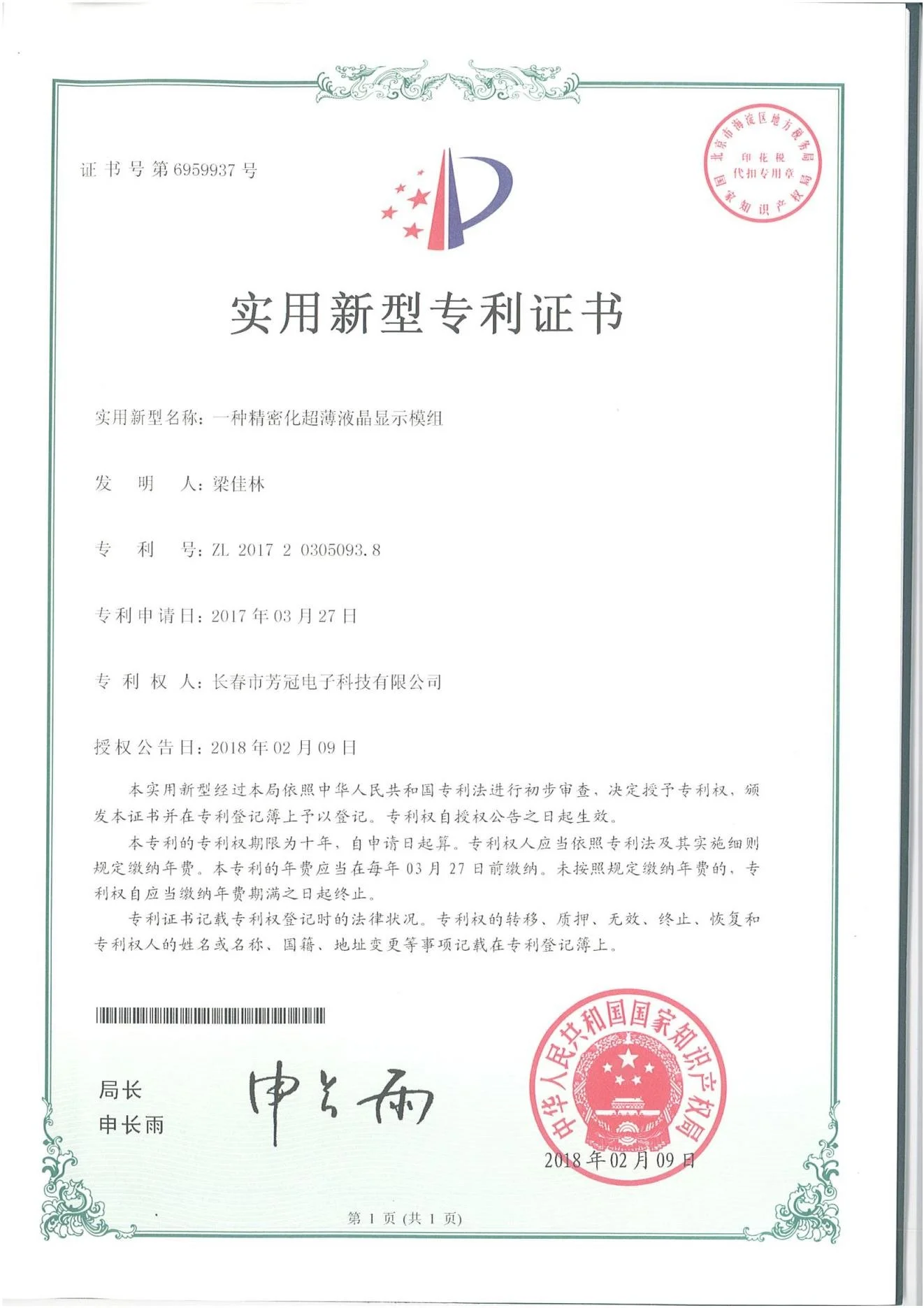

Changchun Fangguan Electronics Technology Co., Ltd. has spent more than a decade perfecting the art of the LCD display. From its automated production lines in northeast China, the company supplies crisp, durable, and power-saving panels to brands in telecommunications, medical devices, automotive electronics, and more.

The table shows some customized cases and is for reference only.

Below is an at-a-glance overview of what makes Fangguan Electronics a partner of choice for anyone who needs a reliable LCD display today—and the capacity to scale tomorrow.

Product Highlights: What Sets Our LCD Display Apart

High Resolution & Sharp Contrast

Proprietary cell-gap control and premium polarizers give every LCD display from Fangguan Electronics exceptional clarity—ideal for diagnostic imaging, industrial inspection, and premium consumer gadgets.Wide Viewing Angles

Optimized alignment layers and backlight diffusion ensure the screen remains legible even when viewed off-axis, a must for automotive clusters and point-of-sale terminals.Energy Efficiency

Low-leakage driver ICs, adjustable backlight currents, and optional reflective modes cut power draw by up to 20 % compared with conventional LCD technology, extending battery life and lowering heat dissipation.Robust Durability

Each LCD display passes stringent drop, vibration, and -30 °C to +80 °C thermal-cycling tests, making it suitable for harsh industrial or outdoor environments.

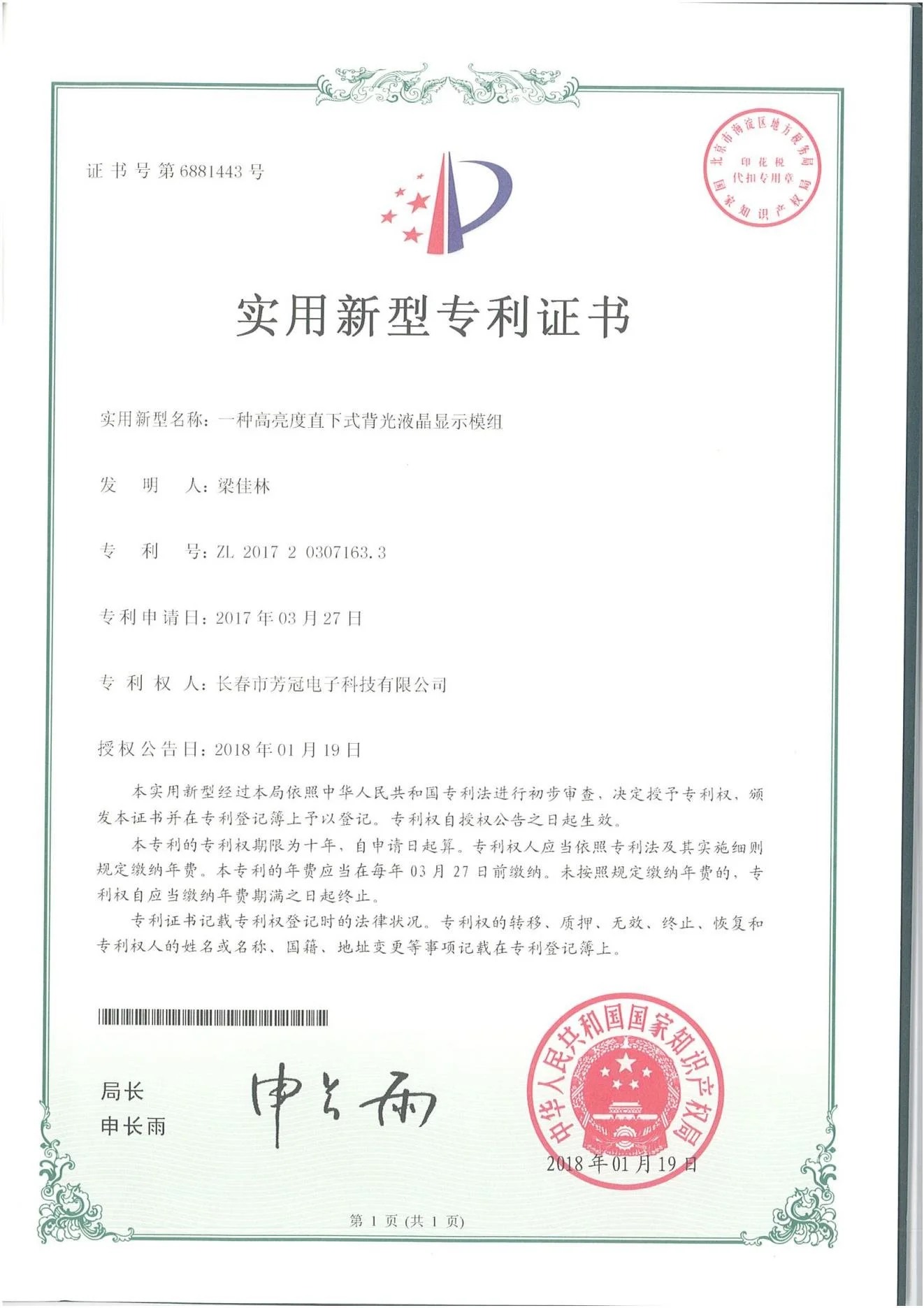

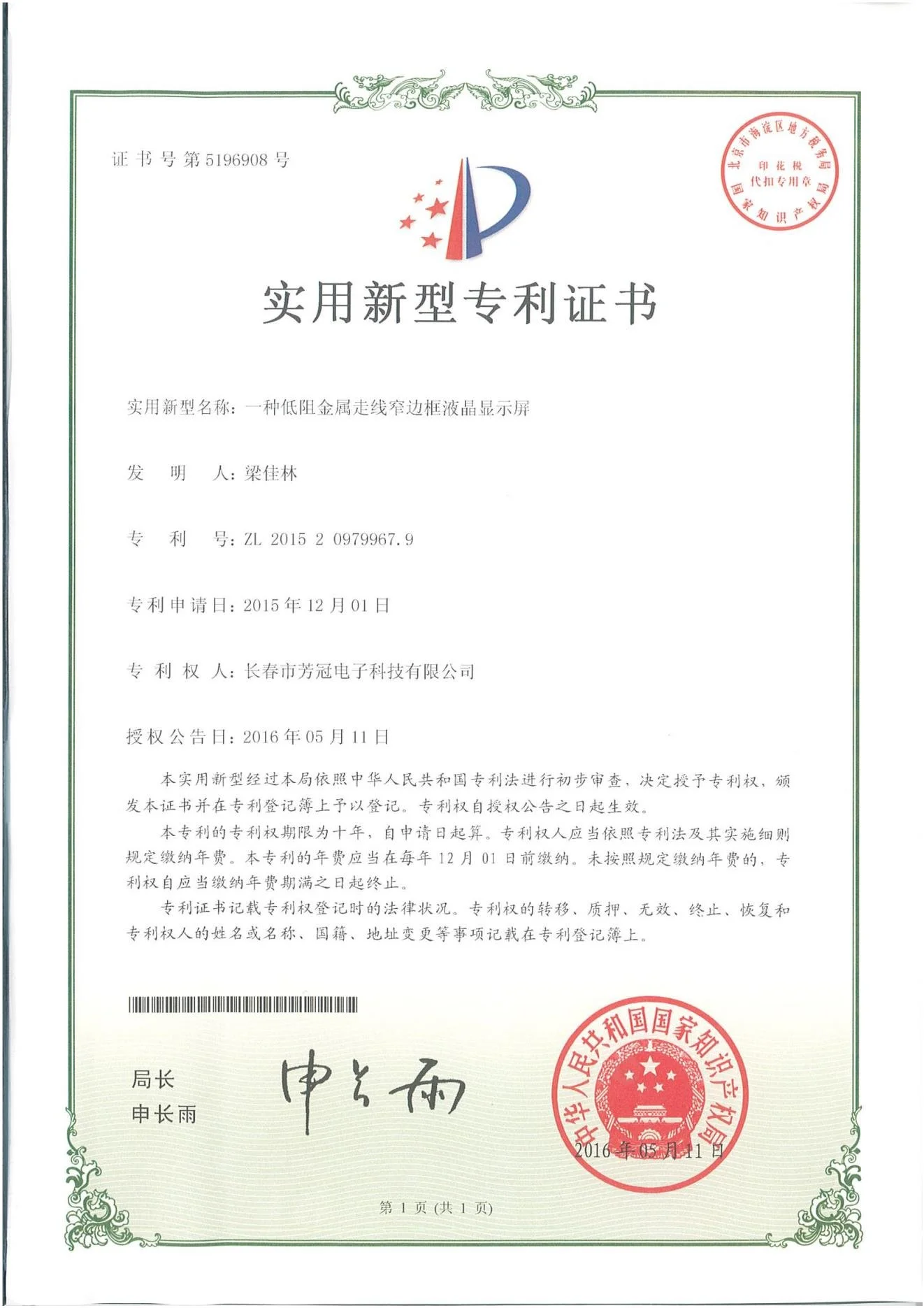

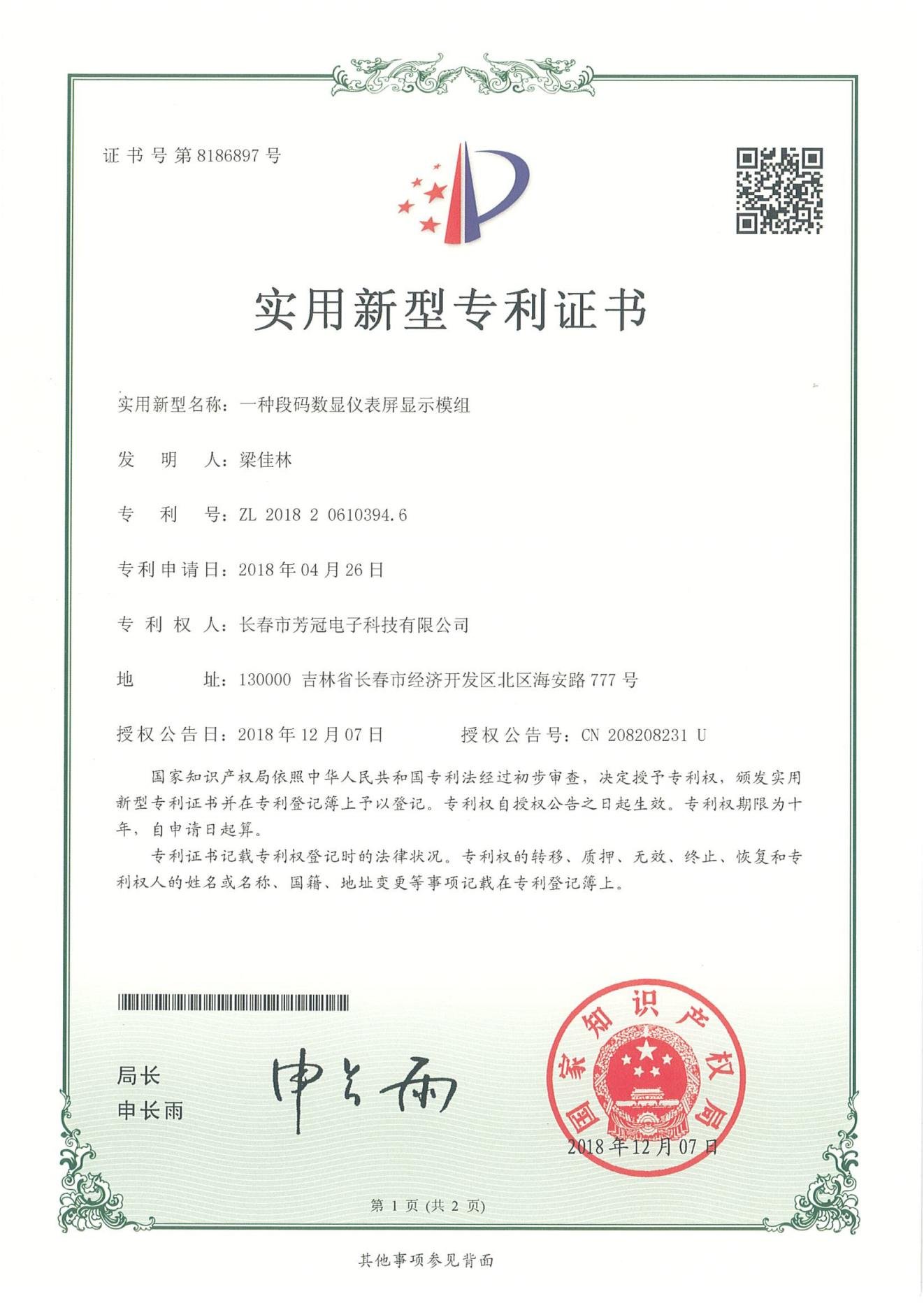

Production Capability & Technology Leadership

Fangguan Electronics operates a fully automated, 50,000 m²-per-year glass-processing line and can assemble 20 million LCD modules annually. Core product families include:

Advanced COG/COF bonding, full-area AOI inspection, and 6-sigma SPC monitoring keep yield rates above 99.5 %.

Versatile Applications of Our LCD Display

Smart Payments & Communication – POS terminals, USB keys, ETC readers

Healthcare & Wearables – Portable monitors, blood-glucose meters, smartwatches

Automotive Electronics – HUDs, instrument clusters, rear-seat entertainment

Industrial Automation – PLC panels, robotic HMIs, precision meters

Consumer & Home Appliances – E-readers, thermostats, kitchen displays

One-Stop Customization & Service

Private-Label Branding – Add your logo to bezels, FPCs, or packaging.

Tailored Mechanics – Free tooling when a single LCD display order exceeds 50,000 pcs; paid tooling with low 2,000-piece MOQ for pilot runs.

Real-Time Factory Streaming – Live video feeds let you witness every process step, from glass cutting to final burn-in.

Rapid Sampling – Typical prototypes ship in 15 days; mass production starts once you sign off on performance and design.

-

-

-

-

Paid molds or Free molds

MOQ: 2000pcs

≥50,000pcs

Molds for free

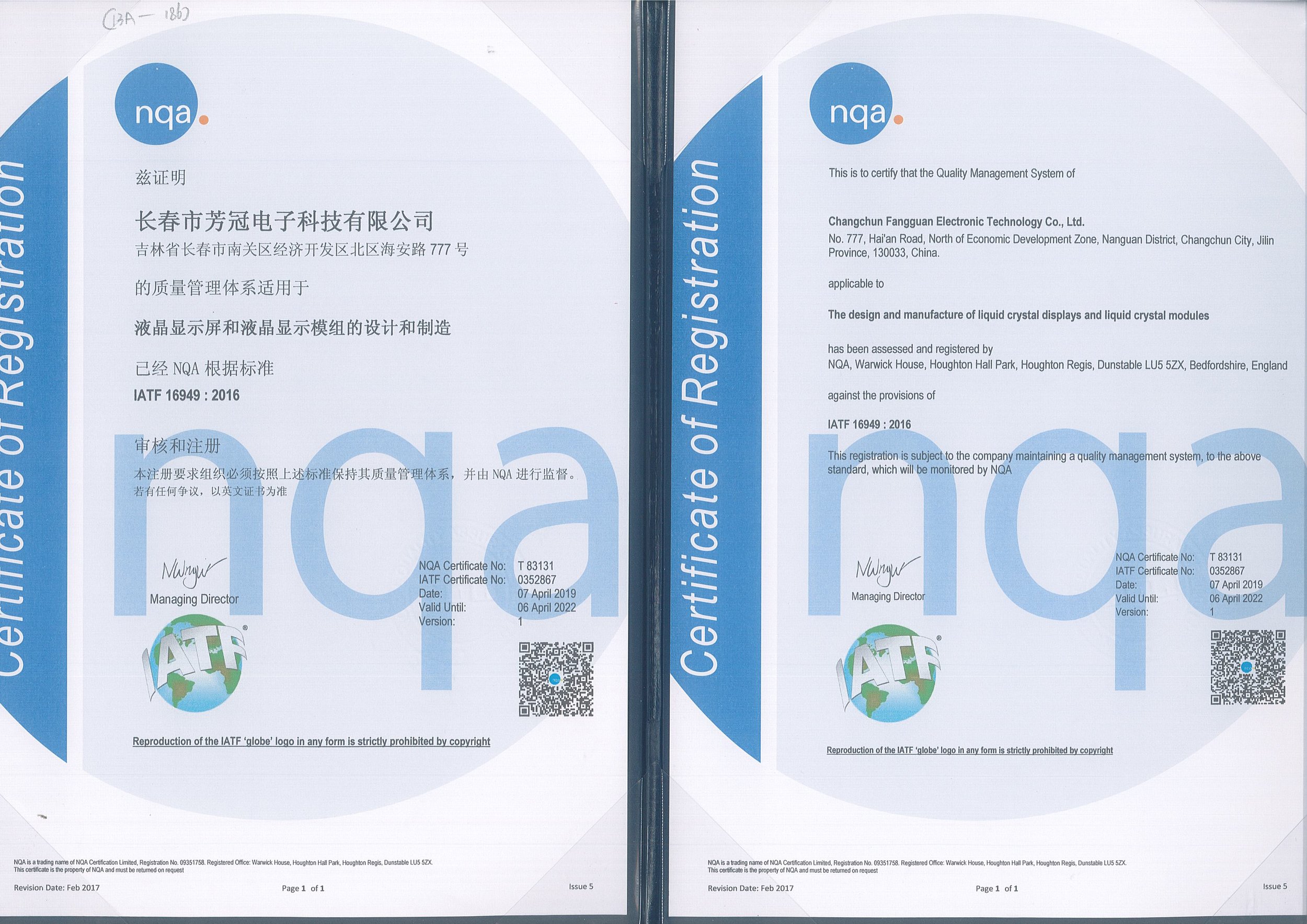

Quality Assurance & Reliability Tests

Every incoming material is verified by IQC and ESD stress tests. Inline AOI vision systems inspect each LCD display cell, while outgoing modules endure:

100 % functional test (contrast, response time, power, dead-pixel check)

High-temperature operating life (HTOL) and thermal shock

1.0 m free-fall and 10 Hz–500 Hz vibration profiles

The result: field failure rates below 50 ppm.

Global Market Presence & Growth Potential

Domestic coverage spans all major provinces, and exports already reach Japan, South Korea, Singapore, and India. North America and the EU are the next expansion targets, supported by double-digit annual compound growth in LCD display demand for EVs, IoT, and smart-home devices.